From First Chill to Final Test: Navigating Furnace Repair Decisions with Confidence

Assessing a furnace issue starts with clear symptoms, but good planning goes deeper. Listen for new noises, verify airflow at each register, and document any burner irregularities. Homeowners benefit from noting when problems appear—at start-up, mid-cycle, or shutdown. That timeline helps a technician trace faults efficiently. Meanwhile, check filters and thermostat settings, since simple fixes can mimic bigger failures. Early observations shorten diagnostic time and reduce avoidable return visits.

Scoping the work requires aligning expectations with system age and service history. Older units may merit targeted repairs now and a replacement roadmap later. Newer systems often justify deeper troubleshooting because parts support is strong. In practice, asking for a parts-and-labor breakdown clarifies whether a short-term fix makes sense. A well-scoped approach accounts for safety checks, like gas pressure validation and heat exchanger inspection, before any cost decisions are finalized.

Staging the service call helps minimize disruption and protects your home. Clear access to the furnace, electrical panel, and gas shutoff saves time. Beyond that, ensure pets and kids are away from the work zone. Technicians can then sequence tasks: intake inspection, electrical tests, ignition verification, and combustion analysis. Proper staging reduces rework and creates a smooth path to restore heat quickly without shortcuts that might compromise performance.

Verifying airflow is central to reliable heating outcomes. Dirty filters, collapsed returns, and blocked supply runs force equipment to work harder. Duct adaptations, like sealing and balancing, often pair well with Heating Installation and Repair and can extend furnace life. If you use add-ons such as humidifiers or advanced filtration, confirm compatibility. Balanced airflow supports even temperatures and lowers stress on blowers, inducer motors, and safety controls.

Calibrating controls ensures the system responds predictably. Thermostat configuration, fan profiles, and limit settings must match the furnace’s specifications. Then, flame quality and sensor feedback are validated under load. When components like igniters, flame sensors, or gas valves show drift, timely replacement prevents nuisance lockouts. Technicians should also inspect condensate routing on high-efficiency models to avoid shutdowns linked to clogged traps or frozen lines during cold snaps.

Budgeting for repairs benefits from lifecycle thinking. A moderate repair on a mid-life unit can be wise, while repeated part failures on an aging furnace hint at diminishing returns. Often, bundling upgrades—like Indoor Air Quality improvements or smart thermostats—during a scheduled visit trims labor overlap. Ask for warranty details on replaced components and document service results so future decisions reflect performance trends rather than guesswork.

Compliance and safety checks are nonnegotiable in any furnace repair plan. Gas leak testing, combustion tuning, and proper venting validation protect occupants and property. Inspecting electrical connections, grounding, and breaker sizing supports stable operation. For homes with mixed systems—Ductless AC or Heat Pump Services alongside a furnace—ensure wiring and controls are harmonized. Cross-system verification prevents conflicts that cause intermittent faults hard to trace later.

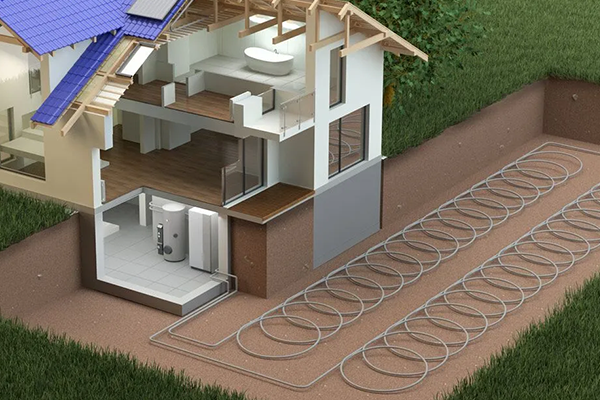

Seasonal timing influences both urgency and availability. Scheduling maintenance before peak cold provides a buffer to refine settings and address borderline components. However, if failure strikes mid-winter, ask about temporary measures that keep pipes safe while parts arrive. Geothermal HVAC and Generator Installation may also affect priorities; keeping backup power and alternate heating integrated reduces downtime when the grid or outdoor conditions complicate service windows.

Vendor fit affects long-term comfort more than many realize. Look for clear communication, transparent findings, and documented results after each visit. The best relationships include proactive reminders, accessible records, and straightforward next-step guidance. HVAC providers who can support AC Installation and Repair and Electrical Services simplify planning, since many furnace issues intersect with power quality, controls, and ventilation that span multiple trades.

Finally, a robust handoff after repair closes the loop. Request final readings—temperature rise, static pressure, combustion metrics—and a plain-language summary of what changed. Validate that thermostats, filters, and access panels are reset correctly. Keep notes on part numbers and dates for future reference. With careful staging, thorough verification, and thoughtful budgeting, you’ll maintain reliable heat while avoiding rushed decisions that lead to repeat breakdowns.